V R TECHNOLOGY

FLOW PRODUCTS EXPERTS

FLOW PRODUCTS EXPERTS

Butterfly Dampers are considered ideal for a wide range of applications that demands low-leakage isolation or flow control operations. Simple & Cost effective product.

Seismic dampers permit the structure to resist severe input energy and reduce harmful deflections, forces and accelerations to structures and occupants. There are several types of seismic dampers namely viscous damper, friction damper, yielding damper, magnetic damper, and tuned mass damper.

Diverter gates are used to change the direction of flow of bulk materials as they are discharged from equipment above.

Diverter gates from HMA Materials Handling can be of two designs, depending on the characteristics of the material being handled. A simple flat blade diverter is applicable for most materials and is relatively inexpensive and easy to install and maintain. For some material, the non-jamming characteristics and sealing capabilities of the rolling blade diverter make it more suitable. Applications:

The louver type of damper consists of several blades mounted parallel across duct, with centrally pivoted shafts.

The louver type of damper consists of several blades mounted parallel across a duct, with centrally pivoted shafts extending out through a frame and driven by a linkage. Louver dampers are versatile, able in theory to handle any application in the power plant.

A slide gate has a flat closure element that slides into the flow stream to stop the materials and high pressure.

In the steelmaking process, one of the most significant refractories for continuous steel casting is the slide gate plate, which is used for precise flow control and safety. Slide gate plates, as indicated in the diagram below, regulate the flow of steel from the steel ladle to the tundish. Because they come into touch with hot liquid steel, the refractories used for slide plates should have higher hot strength qualities.

It allows flow of dust and maintain airlock across the valve. Available in several designs and technical specifications.

Double flap valves have two trap-door flap plates which open and close on an alternating cycle. The top gate opens to allow collected material to drop through onto the bottom gate. The top gate then re-closes to prevent air leakage above the valve. The bottom gate then opens to allow material to pass completely through the valve. The bottom gate then re-closes to prevent air leakage below the valve. This cycle is continuously repeated in order to maintain a steady discharge of material from the valve, while maintaining a positive seal on the system.

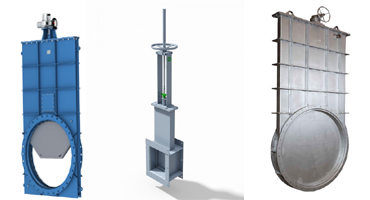

Guillotine dampers can be used in any application where a positive location is required for routine maintenance and Isolation process.

Guillotine dampers are named for their resemblance to the French guillotine. The blade of the damper is able to fully retract out of the flow, minimizing any added pressure drop. When the blade is released, it fully seals against the frame to shut off the flow.

Bag filter, or fabric filter is an air pollution control device and dust collector that removes particulates or gas released from commercial processes out of the air. Cement Plants, Power plants, steel mills, pharmaceutical producers, food manufacturers, chemical producers and other industrial companies often use baghouses to control emission of air pollutants.

Industrial fans and blowers are machines, whose primary function is to provide and accommodate a large flow of air or gas to various parts of a building or other structures. This is achieved by rotating a number of blades, connected to a hub and shaft, and driven by a motor or turbine.

Suitable for conveying bulk powder material with low pressure air an aeration bed and small incline (gravity). Simple in Construction & Operation. It has Open and Close Type.

Airslide Air Gravity systems provide high capacity material handling while offering many economical and environmental advantages. Energy requirements are minimal because only a small volume of air at a low pressure is required to move material. Since the system is installed overhead, valuable floor space and added headroom are available for other purposes. By eliminating the need for massive support members, it permits a flexibility of plant design not available with straight-line conveyors. The Airslide conveyor is dust tight. As a result, the system is extremely friendly to the environment.